In the past two years, with the advancement of the full mechanization of the whole process, a picking and harvesting machine for the segmental harvesting of peanuts has exploded the agricultural machinery market. For a time, the peanut machine market is competitive, and the good and the bad are mixed, so that farmers confusing. In the ups and downs, there is a brand product that stands out. It is from Zhengzhou Zhonglian—Zhonglian Harvest 4HZJ-2500 Peanut Picking and Harvesting Machine. Through the introduction of many articles in the editor, I believe that everyone is interested in this machine. Type has a basic understanding. In this detailed article, The report will go deep into the chassis system of this peanut machine and solve every technical detail surrounding each component of the chassis for the user. Well, do n’t gossip, just start the question.

The first lecture, power system.

Zhonglian harvested 4HZJ-2500 peanut machine equipped with a full diesel Country III engine, model: 4D3-140U32; standard power 88kw / 120 horsepower; fuel injection form: electronically controlled single pump; environmental protection key components: ECU, turbo , Intercooler, fuel injection pump, fuel injector, exhaust muffler, etc. Users can also choose Changchai engines, which is mainly to increase the diversity of supporting power to meet the needs of different users.

The basic parameters of the power system are as follows:

Table 4-1: Basic parameters of 4HZJ-2500 power system of Zhonglian

No. | Power System Project | Unit | Parameter |

1 | Engine manufacturer | / | quanchai/changchai |

2 | Engine model | / | 4D3-140U32(quanchai)/4G33V16(yuchai) |

3 | Calibration power | kw | 88 |

4 | Calibration speed | r/min | 2400 |

5 | Fuel tank capacity | L | |

6 | Gearbox manufacturer | / | |

7 | Gearbox model | / | mechanical |

8 | Gear | / | 3+1Mechanical shift |

Why did the designer choose Quanchai Power? I believe that many old operators also know the reason. In the low-speed agricultural machinery industry, the full diesel engine has many advantages such as high torque, good reliability, convenient maintenance, good service, and high cost performance. It is widely used in the field of harvesting machinery. The brand name is really good. Therefore, it can be seen that the wide application of the full diesel engine in the agricultural machinery industry is because its power, reliability and fuel economy are trustworthy.

In addition, Zhengzhou Zhonglian is an old-fashioned harvesting machine manufacturer. Before using the national III engine assembly, there will be an additional test run for the engine and the whole machine to achieve the best matching and stability. Farmers can rest assured that with such double insurance, the surging power of the whole diesel engine can be fully released.

Everyone knows that after NationalⅡ rose to NationalⅢ, air filtration has become an independent key component, and it is also particularly conspicuous from the outside. This is because diesel atomization and complete combustion require high-quality clean air as a guarantee. This full diesel engine adopts a high-performance three-stage filter, that is, the air filter element is upgraded to a horizontal paper air filter with three stages of roughening, which can fully remove coarse particles in the air and ensure the fineness of the main filter element Filter effect. Why should we repeatedly emphasize air filtration? First, because the peanut machine operates in a high dust concentration environment for a long time, it is necessary to ensure that the engine can work normally and also to minimize the auxiliary time for maintaining the air filter. Three-stage filtration measures are necessary It is also necessary; secondly, if the air filter is not tightly sealed, it will cause the air to enter the engine without filtering, causing wear of the cylinder, and the trouble will be great.

Speaking of which, do you understand? This newly upgraded air filter system of Quanchai State III can ensure the air flow at the air filter outlet and match the required air supply of the engine at the rated power. Cylinders, pistons and piston rings extend the life of the engine and provide a clean working environment for the engine.

When it comes to National III, we cannot avoid the topic of environmental performance. This full diesel National III electronically controlled single pump injection uses high horsepower turbocharging or supercharged intercooling to achieve true national III emissions without pressure. Compared with the wheat machine, because the peanut machine has an additional grass box, the engine position is moved forward to the right of the cab, which squeezes the cab position to a certain extent, but it has many advantages for the engine: the engine is arranged side by side and independent Area space, water tank and radiator are all on the outside, which is conducive to heat dissipation, impurity removal and maintenance. You can understand it this way: The engine originally lived in a "multi-person room", but now it has been in a "single room". The power performance, environmental protection performance and adaptability are definitely improved.

Second lecture, when it comes to drive axle.

The drive axle is the "mainstay" in the chassis. If the engine is broken, it can be replaced as a whole. If the drive axle is broken, it will basically be scrapped. Make sure to keep your eyes clean when choosing a machine. If you don't understand, just look at the introduction of The report. Experience is that professional factories are more secure.

The main drive axle of Zhonglian Harvest 4HZJ-2500 peanut machine is mainly equipped with: gearbox assembly, continuously variable transmission assembly, walking clutch, wheel reducer assembly, left and right axles, hand brake foot brake mechanism, wheel rim tire component. Generally speaking, this is the case for harvesting machinery.

First, the speed change mode and the number of gears are relatively satisfactory. Equipped with a stepped mechanical gearbox 3F + 1R, 3 forward gears, 1 reverse gear; the main clutch adopts gear shifting, very mature components, small impact, low noise, light and flexible shifting; in each forward gear It can realize hydrostatic driving, and the speed can be changed through the speed-adjusting handle, which makes the operation more portable. It should be said that such a configuration is not luxurious, but there is no pressure to meet the requirements of large-scale cross-region operations.

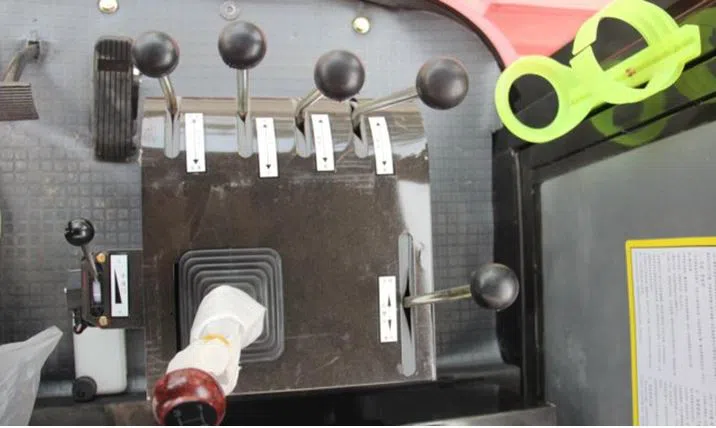

Second, stepless speed increase torque, this is a high-end configuration. With it, it can ensure that the torque is more stable and stable under complex conditions. As mentioned earlier, the mechanical gearbox 3F + 1R travel gear has three forward gears Ⅰ, Ⅱ, and III, and a reverse gear. It is configured to meet the requirements of different peanut zones, including cross-zone operations. The driver operates the shift lever. Each gear can be steplessly shifted to achieve high-speed and low-speed switching. Its control handle is on the hydraulic distributor (multi-way valve) in the cab. Push forward to slow down and pull back to speed up, which can effectively improve the operating efficiency.

Third, it is equipped with closed side reduction (wheel side deceleration) of wheat machine, a very useful torque increasing device. In order to further increase the driving force and meet or modify the driving force matching of the entire transmission system, 4HZJ-2500 is equipped with wheat machine side reduction, that is, wheel side deceleration, which can be professionally called internal tooth meshing side reduction. It has maintenance-free, long life and good maintenance. And strong reliability. After the configuration of the side reduction, first, the speed reduction and torque increase effect is more obvious, and the walking is more vigorous; second, it can make the drive axle get a larger ground clearance, higher performance, and effectively reduce the wear on the front tires. The two factors work together, and the transmission torque is greater, which makes it easier to get involved in dangerous situations during the operation and has no worries.

Third lecture, braking performance, steering axle, hydraulic system, we say together.

To give a simple and popular example, if the chassis is installed more than the author, the power system is like structural design, the drive axle is like various pipeline arrangements, and the braking performance system is like surface finishing projects such as scraping putty. In fact, don't look at the differences in importance, in fact, no one can do without others.

First, the function of the braking system is to brake on the road or park on the slope. Harvesting machinery is similar, generally it is hand brake parking and foot brake, which is the same as Zhonglian Harvest 4HZJ-2500 peanut machine. The handbrake is a disc brake. The driver must use the handbrake when stopping on a slope, and must use obstacles to prevent the front and rear four-wheeled feet during maintenance. The foot brake is a disc brake with the same operating principle as the hand brake, but it can be hydraulically assisted.

Secondly, the steering axle, as it is commonly called, is the supporting device of the steering mechanism, but it is only half right. So, how do we evaluate the steering axle of the 4HZJ-2500 peanut machine from a professional perspective? The report tells you to master three key aspects: First, in addition to achieving steering, you can ensure that the machine always drives straight and walks stably. Safe operation, reducing tire wear; Second, it is equipped with a full hydraulic steering system, which can achieve a larger steering torque with less operating force, lighter structure, more flexible operation, safer and more reliable; Third, the connection between the grain tank and the rear axle It is a buffer energy storage device. I call it a flexible connection. In addition to supporting the rear weight of the combine, it can ensure walking in different terrain and road conditions, offset the left and right shake caused by uneven ground, and prevent rollover. Maximize the balance of the grain tank.

Whether the steering axle combination can be perfectly combined in the above three aspects is an important indicator for measuring the quality level. Of course, the inclination and dynamic balance of the assembly are very important. Maybe this is the difference between a brand machine and a knock off machine.

Third, the design of the hydraulic system of the 4HZJ-2500 peanut machine of Zhonglian Harvest mainly accomplishes the following functions: hydraulic steering, lifting of the picking table, lifting of the fruit box and grass box, and stepless speed change. We can also consider the hydraulic system as a peanut Another source of power for the aircraft, stability and safety are very important.

Through the detailed explanation of the chassis system, we finally unlocked some of the technical secrets of 4LZJ-2500 peanut machine harvested by Zhonglian. I believe it will be helpful to farmers. Finally, I would like to point out that in the design of the chassis of Zhonglian Harvest, the whole process reflects the concepts of safety and convenience. That is to say, people are always considered as the first element of design. A big highlight.

Finally, let The report further summarize and state that the chassis system of Zhonglian Harvest 4HZJ-2500 inherits the manufacturing essence of Zhonglian wheat harvester and corn machine. Zhengzhou Zhonglian "goes more and more specialized" on the road of harvest machinery. They Products make consumers more and more assured.