Small Combine Harvester

Home > Product > Agriculture Equipment > Small Combine Harvester

The cleaning fan adopts an adjustable air volume cross flow fan to make the corns and its seeds clean, no impurity.

Performance

1. The cleaning fan adopts an adjustable air volume cross flow fan to make the corns and its seeds clean, no impurity.

2. Using straw crushing and returning device, can completely crush the corn straw and reduce the stubble height.

3. Assembling shake sieve and seed recycling bins, can collect the fallen corn seed, reduce loss rate.

4. Flexible harvesting ways, suitable for different row space and different planting structure, can harvest even not in rows.

5. Adopt closed, shock-absorbing and big-sized glass cab, comfortable and clear visibility to drive.

6. Short machine body, short front-back wheel distance, small turning radius, easy to turn around in field.

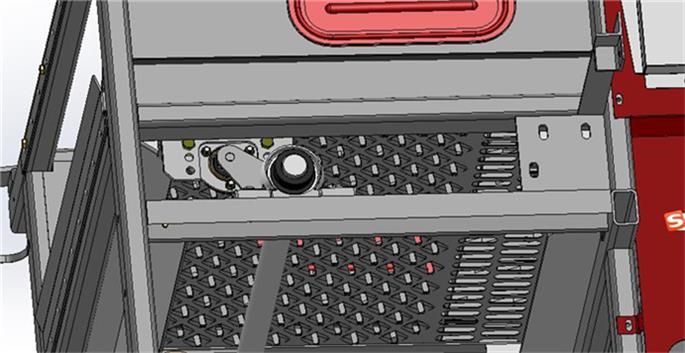

Parts Details:

1.When the peeling device working, if there are small corn stalk stuck to the peeling rollers, No.1 gear will make a strange noise, and it is necessary to stop immediately to adjust the gap of the peeling roller.

Adjustment method: First check which group of peeling rollers belong to making abnormal noise, then loosen the spare nut at 2 place, twist the other nut, and press the spring,can eliminate the abnormal noise.

2.The v-belt of the transmission power on the peeling device(3 in the figure) needs to be checked for tightness during the work day, loose and tight in time.

Adjustment method: adjust the nut on the tightening screw to raise the height of the pinch wheel. The higher the tightening, the tighter the tightening.

1. If the peeling is not clean during use, the pressure transmitter adjustment handle on both sides of the peeling machine can be adjusted.

2. Adjustment method: first pull one pull rod outward, then move the two adjustment handles upwards, so that the flexible star pressure feeding wheel is pressed down to solve the problem that the corn cobs in the granary are not cleaned.

3. Move the two adjustment handles down to solve the problem of excessive peeling, resulting in threshing phenomenon (there are 4 adjustments at the same time on both sides).

4. Can adjust the angle of the vibrating sieve if the vibrating sieve is unclean during use.

5. Adjustment method: the peeling machine vibrating sieve’s drive shaft (3 in the picture), the bolt fixing position on the bearing seat plate can be adjusted.

6. Adjust to the upper end to solve the problem of unclean;

7. Adjust to the lower end to solve the problem of too much blockage due to the bractea.

FAQ:

Q1. How long is the delivery date for small maize combine harvester ?

A: In general, we can ship the goods within 15 days after receiving your payment. Of course, it also depends on your quantity.

Q2. Packaging & Shipping

1.We need to apart some parts from the small maize combine harvester,such as the header,cab,peeling machine,tank and so on,then it can load to the container,one 40' high container can loading one set.

2.We can deliver the goods to you by sea, by air, by express or by land transportation. We will try my best to make you get the goods faster and safe.

Q3. After-Sales Service

1. Training how to install and use the machine,engineers available to service machinery overseas.

2. Warranty period of one year since machine arrives destination port. Malfunctions which are caused by machine-self and quality will be responsible for our manufacturer. Other malfunctions which caused by operation mistakes, man-made problems, etc will be responsible for clients-self.

3. Timely response to customers’ problems 7*24 hours, provide in time Feedback tracking and after-sales services to maximize the customer’s satisfactory.

Technical Parameters:

Model | small maize combine harvester |

Type | Wheel type |

Wheel | 2 drive wheel + 2 direction wheel |

Function | Picker + peeling, produce “corn cob” |

Model of engine | 4H11 |

Power | 103kw (140 hp) |

Engine speed | 2300-2400 r/min |

Harvester rows | 3 rows |

Cutting width | 1825mm |

Harvest efficiency | 0.27~0.53 hm2/h |

Total loss rate | ≤4% |

Breakage rate | ≤1.0% |

Impurity rate | ≤1.5% |

Peeling rate | ≥85% |

Oil consumption | ≤20kg/hm² |

Minimum corn cob height from field | 300mm |

Granary volume | 6190×2300×3259mm |

NW | 4990 Kg |

Size | 6190*2300*3259mm |

Corn Harvester Display Viewing: