Picker

Home > Product > Harvest Machinery > Picker

The machine is mainly used for peanut direct harvesting or drying harvesting after peanut unearthed. Completing peanut gathering, picking out, fruit vine separating and into the tank respectively at same time.;with its strong performance, compact structure

Introduction:

The machine is mainly used for peanut direct harvesting or drying harvesting after peanut unearthed. Completing peanut gathering, picking out, fruit vine separating and into the tank respectively at same time.;with its strong performance, compact structure, easy operation, durable safety,the machine adapts to all the land that machine can work. Provide customized and differentiated product according to the requirements.We can make tools of specific length and thickness according to customers’ requirements and make our products more adapted to the special work conditions.

Feature:

1. Sealed cab, reduces the noise, makes the driver feel more comfortable.

2. Using centrifugal fan to send grass, has good fruit&grass separation effect and cleaner forage.

3. Clods cleaning adapts airflow pattern to prevent clogging and reduce the rate of broken peanut fruit.

4. The machine has two tanks, one tank for the peanut, the other tank for the peanut vine which will be crushed as forage.

5. Removing dust downward, reduce the dust to extend the machine’s life.

6. The picker uses a double track to run smoothly, adopts the circulation mode picking device, improve picking efficiency.

7. The height of picker, speed of roller and fan are visual by a digital display.

8. Famous brand engine, optional 120/130/140HP, more powerful, more economical, more energy-saving, also be environmentally friendly.

9. Soft peanut picking and low grain breakage rate, low impurities rate.

10. User-friendly design, FRP material used on its body, beautiful appearance.

11. The new hydraulic control is operated, the mobile phone charger and hands washing sink are added, to make the driving comfort is more humanized.

12. It adopts D3.5 type large clutch gearbox, which is reliable and durable. It has long clutch arm to save energy.

13. According to the user's needs, optional rear brake steering axle; optional mechanical rear drive; optional hydraulic rear drive; more adaptable.

14. Rotary dust cover device to avoid water tank will be high temperature after a long time working.

15. Bigger fuel tank; longer endurance working time. Optimize the hydraulic system of the whole machine with high reliability.

16. The forage tank can be equipped with dust reduction system(optional), reduce dust to protect the environment.

17. Adopt famous brand bearings, and high-speed maintenance-free bearings are applied in key positions, easy maintenance and low failure rate.

18. Technical parameters:

Specification | Type No. | 4HZJ-2500 |

Structural style | self-propelled wheel type | |

Function picking | crash and collect the straw | |

Size ( L*W* H ) | 6485*2770*3420mm | |

Net weight | 5250kg | |

Gear box | mechanical | |

Engine power | 120 hp | |

Cutting width | 2500 mm | |

Work efficiency | 0.27—0.54 hm2/h | |

Total loss rate | ≤ 3.5% | |

Broken rate | ≤ 2.0 % | |

Impurity rate | ≤ 5.0 % | |

Stem recovery rate | ≥ 93 % | |

Unloading way | mechanical unloading | |

Fruit unloading height | 2300 mm | |

Grass unloading height | 2120 mm | |

Fruit tank volume | 2.35 m³ | |

Grass box volume | 5.3 m³ | |

Type of drive | 2 wheels drive | |

Transportation and Package | 1 set in a 40'HC (dis-assembled ) |

FAQ:

Q1.How long is the delivery date?

A:In general, we can ship the goods within 15 days after receiving your payment. Of course, it also depends on your quantity.

Q2. How can I visit your factory?

A:We are located in Zhengzhou city,middle of China,Airport&High-speed train, the transportation is very convenient

Q3: What's your main products?

A: Our products are covered rice&wheat combine harvester,corn harvester and peanut harvester.

Q4. What is your terms of payment?

A: T/T, L/C, Paypal,Western Union

Q5: How is the quality of the harvesrter?

A: We are an experienced manufacturer which has been in this field for 30 more years, and can supply high quality harvesters for you.

Packaging & Shipping

1.We need to apart some parts from the whole machine,such as the header,cab,peeling machine,tank and so o,than it can load to the container,one 40' high container can loading one set.

2.We can deliver the goods to you by sea, by air, by express or by land transportation. We will try my best to make you get the goods faster and safe.

After-Sales Service

1.Training how to install and use the machine,engineers available to service machinery overseas.

2.Warranty period of one year since machine arrives destination port. Malfunctions which are caused by machine-self and quality will be responsible for our manufacturer. Other malfunctions which caused by operation mistakes, man-made problems, etc will be responsible for clients-self.

3.Timely response to customers’ problems 7*24 hours, provide in time Feedback tracking and after-sales services to maximize the customer’s satisfactory.

4.Spare parts are always available. You just feedback the parts No. to us per the instruction manual, we will do all the other job for you.

Small Peanut Harvester

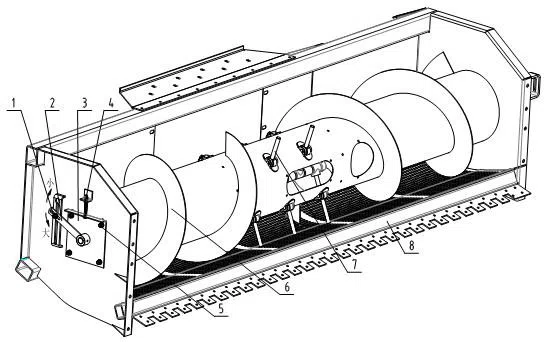

Figure 7 Adjustment of auger clearance

1. Telescopic tooth adjustment bolt and nut 2. Spring tooth adjustment handle 3. Stirring adjustment plate 4. Adjust plate adjustment bolt and nut 5.Adjustment plate fixing bolts 6.Auger blades 7.Telescopic tooth 8.Pickup floor

Adjustment The Security Clip Of Picker

The pick-up platform safety clip is used for repairing the pick-up platform, adjusting the height of the pick-up tooth, and driving on the road.

The adjustment method (refer to Figure 8):

a. Raise the picking platform first, then remove the hanging chain, so that the safety clip falls on the top pillar of the cylinder, and finally pick up

Platform so that the end face of the safety clip and the end face of the oil cylinder are closely attached and supported.

b. The height of the picking table should be adjusted according to the fit of the picking tooth to the ground. First loosen the lock nut before adjusting the bolt length. Adjust the bolts upwards to increase the length of the pick-up table. Adjust the bolts downwards to reduce the length. Based on the distance between the picking tooth and the ground, the distance between the picking tooth and the ground is basically guaranteed to be 0, and the soil is allowed to enter 10-20mm.

Self-Propelled Peanut Combine Display Viewing:

← No Information