Self Propelled Combine

Home > Product > Agriculture Equipment > Self Propelled Combine

Adopt automatic high-level unloading grain tank,which is suitable for different grain transportation vehicles, labor-saving and quickly unloading.

Self-Propelled Rice Combine

1. Double-layered stepwise sieve for better cleaning, no grass, no chaff,low loss rate.

2. Widen elevator,increase granary, reduce unloading rice times.

3. Sealed cab, reduce the noise, make the driver feel more comfortable, Reserve a termination to connect air conditioner or fan.

4. Adopt automatic high-level unloading grain tank,which is suitable for different grain transportation vehicles, labor-saving and quickly unloading.

5. With a larger water tank,and a new design radiator cover, to ensure the engine will not be high temperature after a long time working under a harsh environment.

6. Adopt 160HP engine and new transmission components, powerful and durable.

7. Enlarge the threshing cabin , lengthen the threshing drum, increase large feeding quantity,high production efficiency.

FAQ:

Q1: How long is the delivery date?

A: In general, we can ship the goods within 15 days after receiving your payment. Of course, it also depends on your quantity.

Q2: How can I visit your factory?

A: We are located in Zhengzhou city,middle of China,Airport&High-speed train, the transportation is very convenient

Q3: What's your main products?

A: Our products are covered rice&wheat combine harvester,corn harvester and peanut harvester.

Q4: What is your terms of payment?

A: T/T, L/C, Paypal,Western Union

Q5: How is the quality of the harvesrter?

A: We are an experienced manufacturer which has been in this field for 30 more years, and can supply high quality harvesters for you.

Packaging & Shipping

1. We need to apart some parts from the whole machine,such as the header,cab,peeling machine,tank and so on,then it can load to the container,one 40' high container can loading one set.

2. We can deliver the goods to you by sea, by air, by express or by land transportation. We will try my best to make you get the goods faster and safe.

After-Sales Service

1. Training how to install and use the machine,engineers available to service machinery overseas.

2. Warranty period of one year since machine arrives destination port. Malfunctions which are caused by machine-self and quality will be responsible for our manufacturer. Other malfunctions which caused by operation mistakes, man-made problems, etc will be responsible for clients-self.

3. Timely response to customers’ problems 7*24 hours, provide in time Feedback tracking and after-sales services to maximize the customer’s satisfactory.

Parts Details

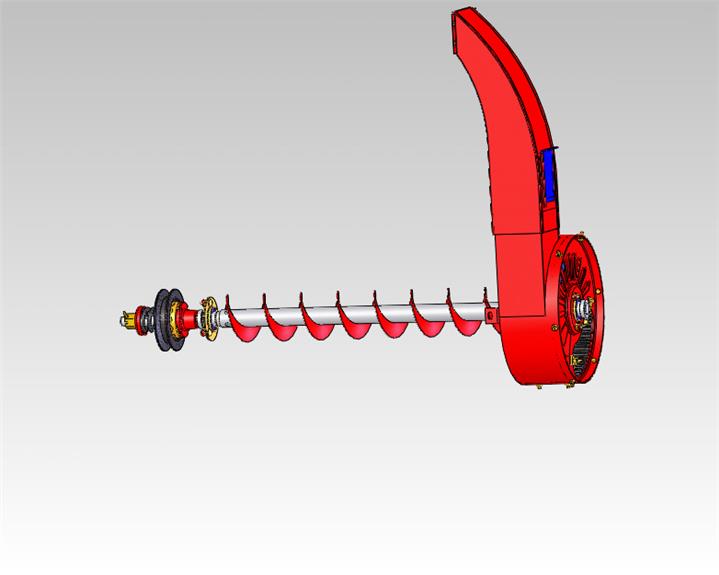

Function: The unremoved residual spikes that are sieved by the residual sieve (mainly the tail sieve) are pushed to the volute of the retort by the agitated auger, and then thrown back to the clearing sieve for cleaning. And can play the role of overload safety protection.

Working principle: When working, the centrifugal force generated by the high-speed rotary impeller is used to form a strong impact and flaw on the raft, and then threshed and thrown into the cleaning chamber.

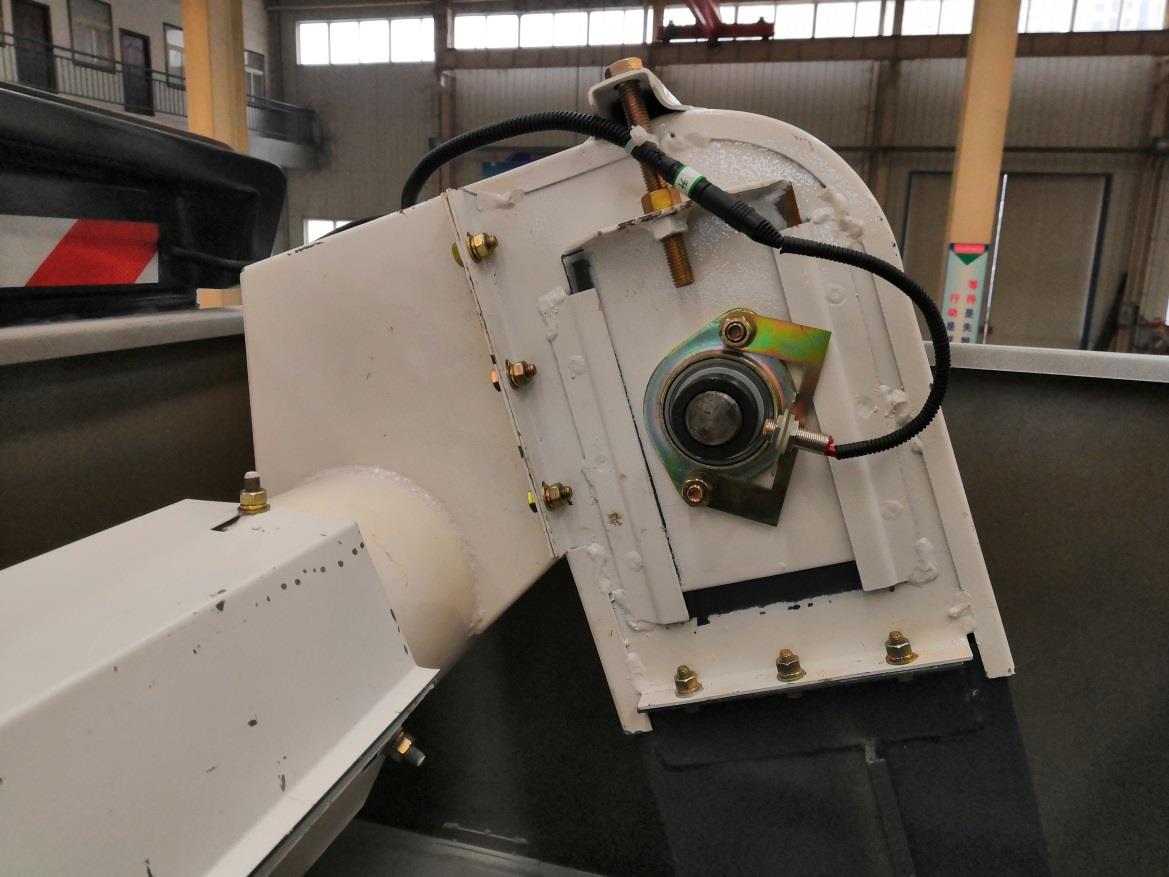

Lift Chain Adjustment

After a period of use, the scraper chain will be elongated, and the tightness of the elevator chain should be adjusted in time. Method: Open the bottom view port of the elevator, and pull the elevator chain by hand, so that the chain can move about 5 mm radially relative to the sprocket, or the blade can be tilted by 30 degrees by hand. . There is no collision sound when the main engine is running normally. In general, the tension of the elevator chain can be adjusted by the left and right adjustment bolts on the upper end of the elevator. If the chain is too tight or too loose, the chain connector needs to be added or removed.

Technical Parameters:

Model | Self-propelled rice combine |

Type | Wheel Type |

Wheel | 2 drive wheel, 2 direction wheel |

Size | 6640*3600*3430 mm |

NW | 6260 Kg |

Function | Cutting,threshing and collection |

Power | 160HP |

Speed | 2200 r/min |

Style | 4 cycle diesel |

Cutting width | 3270 mm |

Feed quantity | 8Kg/s |

Work efficiency | 0.8-1.2 hm²/h |

Oil consumption | ≤20 kg/hm² |

Minimum grain height from field | 290mm |

Grain unloading | Mechanical |

Grain tank | 2000 L |

Fuel tank | 220 L |

Gear box | Mechanical |

Type | Rasp bar |

No. of rasp bars: | 8 |

Cylinder diameter | 550 mm |

Cylinder width | 1020 mm |

Total loss rate for wheat | ≤1.2% |

Total loss rate for rice | ≤3% |

Breakage rate | ≤1.0% |

Impurity rate | ≤2.0% |