Picker

Home > Product > Harvest Machinery > Picker

It is a self-propelled corn harvester, compact design, short body, flexible maneuverability, small turning radius, easy to turn around in field, high harvesting efficiency; newly dynamic appearance, novel and beautiful; easy to maintain

Corn Machine Picker

It is a self-propelled corn harvester, compact design, short body, flexible maneuverability, small turning radius, easy to turn around in field, high harvesting efficiency; newly dynamic appearance, novel and beautiful; easy to maintain; suitable for different row space and different planting structure, can harvest even not in rows.

Main Feature

1.Short machine body, short front and back wheels distance, small turning radius, easy and fast to turn around in field high harvesting efficiency.

2.The header’s reel chain adopts forced feeding way, can harvest the corn not in rows, also can horizontally harvest.

3.Peeling device with special design, adopt soft peeling technology, 4 sets peeling device, 16 pcs rollers, metal and rubber rollers blended, this design.

makes peeling more clean, reduces the rate of seed damage and loss.

4.Using straw crushing and returning device, can completely crush the corn straw and reduce the stubble’s height.

5.Sealed cab, lower noise, wider horizon, make the driver feel more comfortable.

6.Adopt famous engine, which is powerful,durable and low fuel consumption.

Technical Parameters:

Model | maize harvester |

Type | Wheel type |

Wheel | 2 drive wheel + 2 direction wheel |

Function | Picker + peeling, produce “corn cob” |

Power | 103kw (140 hp) |

Engine speed | 2300-2400 r/min |

Harvester rows | 3 rows |

Cutting width | 1825mm |

Harvest efficiency | 0.27~0.53 hm2/h |

Total loss rate | ≤4% |

Breakage rate | ≤1.0% |

Impurity rate | ≤1.5% |

Peeling rate | ≥85% |

Oil consumption | ≤20kg/hm² |

Minimum corn cob height from field | 300mm |

Granary volume | 6190×2300×3259mm |

NW | 4990 Kg |

Size | 6190*2300*3259mm |

FAQ:

Q1. How long is the delivery date?

A: In general, we can ship the goods within 15 days after receiving your payment. Of course, it also depends on your quantity.

Q2. How can I visit your factory?

A: We are located in Zhengzhou city, middle of China, Airport&High-speed train, the transportation is very convenient

Q3: What're your main products?

A: Our products are covered rice&wheat combine harvester, corn harvester and peanut harvester.

Q4: How is the quality of the harvester?

A: We are an experienced manufacturer which has been in this field for 30 more years, and can supply high-quality harvesters for you.

Packaging & Shipping

1. We can deliver the goods to you by sea, by air, by express or by land transportation. We will try my best to make you get the goods faster and safe.

2. We need to apart some parts from the whole machine, such as the header, cab, peeling machine, tank and so o, then it can lead to the container, one 40' high container can loading one set.

After-Sales Service

1. Training how to install and use the machine, engineers available to service machinery overseas.

2.The warranty period of one year since the machine arrives destination port. Malfunctions which are caused by machine-self and quality will be responsible for our manufacturer. Other malfunctions which caused by operation mistakes, man-made problems, etc will be responsible for clients-self.

3. Timely response to customers’ problems 7*24 hours, provide in time Feedback tracking and after-sales services to maximize the customer’s satisfactory.

Corn Machine Harvester Parts Details

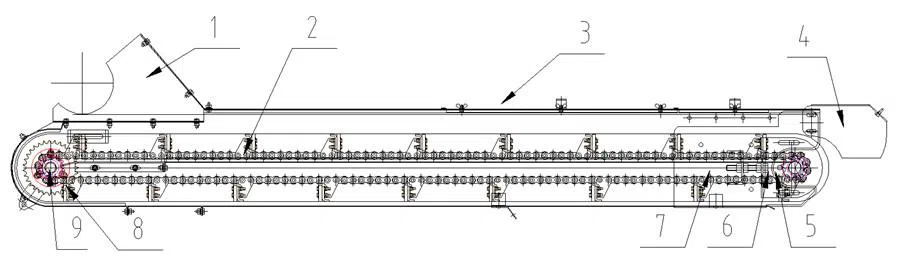

Rear Elevator(P48)

The elevator is used to send the corn ears and stems to the peeling machine. The elevator is composed of a driving shaft of the elevator(9), a lifting chain (2) with a scraper, a movable cover plate (3) on the shell, a passive shaft of the elevator(5), a discharge port(4)and so on. The adjustment of the rear elevator and the bridge elevator is similar.

(P 48)

1.fenders 2.transport chain harrow 3.upper cover plate 4.discharge port 5.elevator driven shaft 6.drivenchain wheels 7.adjustment screw 8.input sprocket 9.elevator drive shaft

(1). Adjustment Of Lifting Chain

In order to make the lifter work normally, must make sure each chain sprocket and the axis of the guide rail in the same plane. The tension of the two chains of the elevator should be the same. The normal tension should be 60 to 80mm height distance from the bottom plate when the chain is lifted from the middle by hand. The chain tension of the elevator is realized by adjusting the screw (2) at the ends of the passive shaft (7) of the lifter.

If the elevator is jammed due to improper operation, can open the movable cover plate (3) to clean the blockage.

(2). Adjustment Of The Discharge Port

The material transported by the elevator to the peeling machine must be evenly distributed, the peeling roller of the peeling machine can work effectively. Make the material evenly distributed can adjust the inclination angle of the discharge port of the lifter. When the harvester is working, the bolts at two ends of the discharge port are released according to the actual situation, adjusted to the appropriate position and then fixed. The discharge port is usually installed in the middle hole position when machine out of the factory.

Corn Harvester Display Viewing: